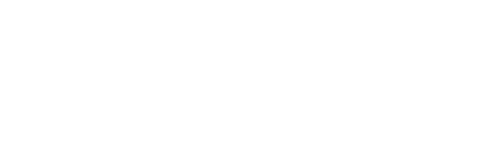

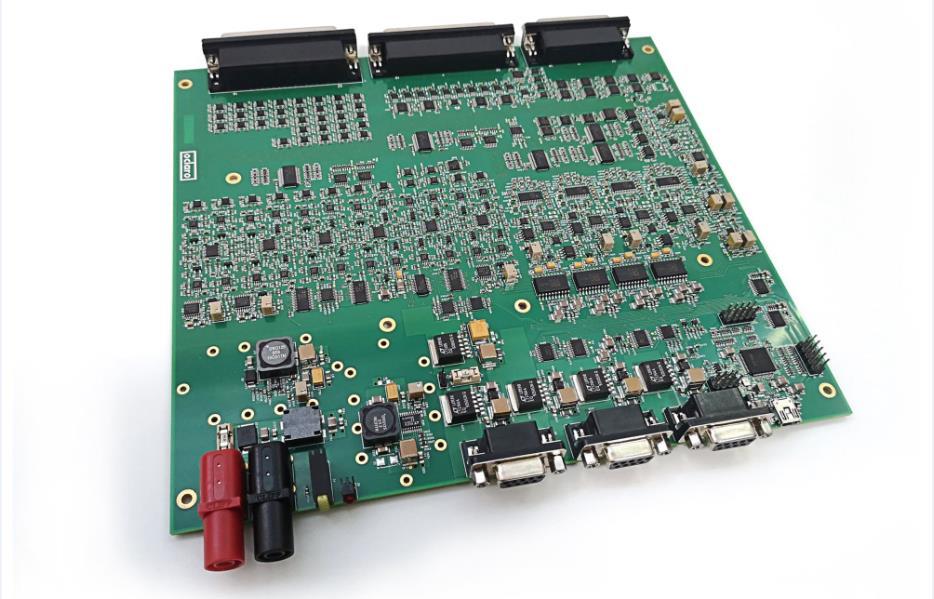

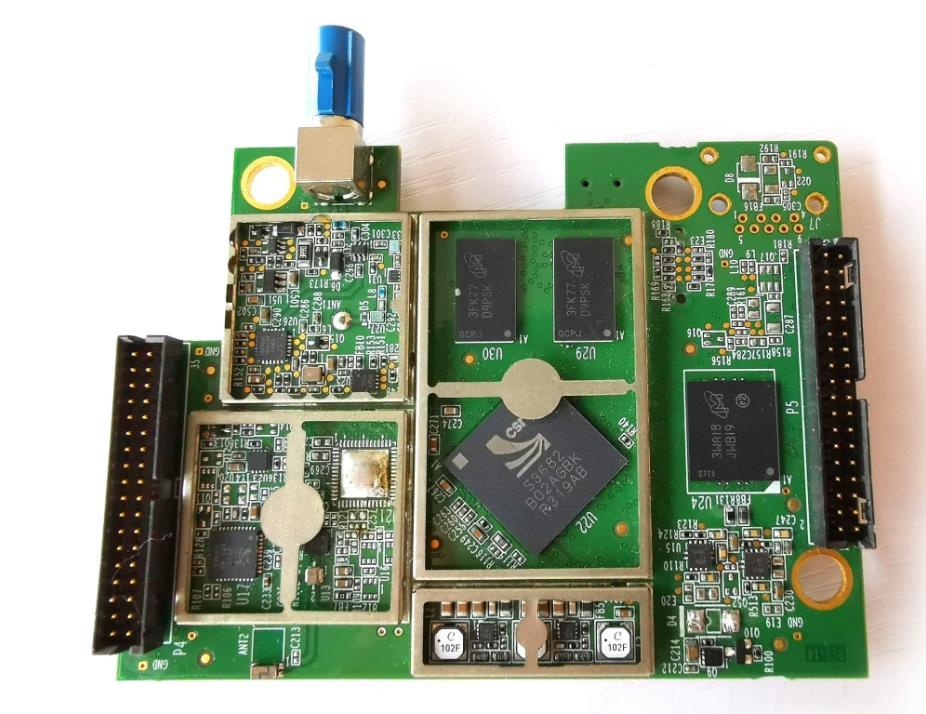

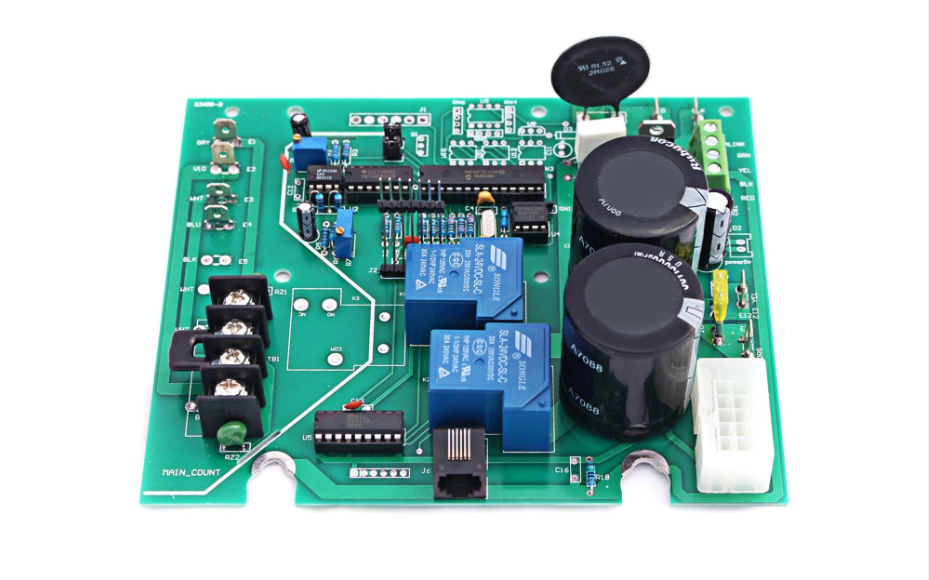

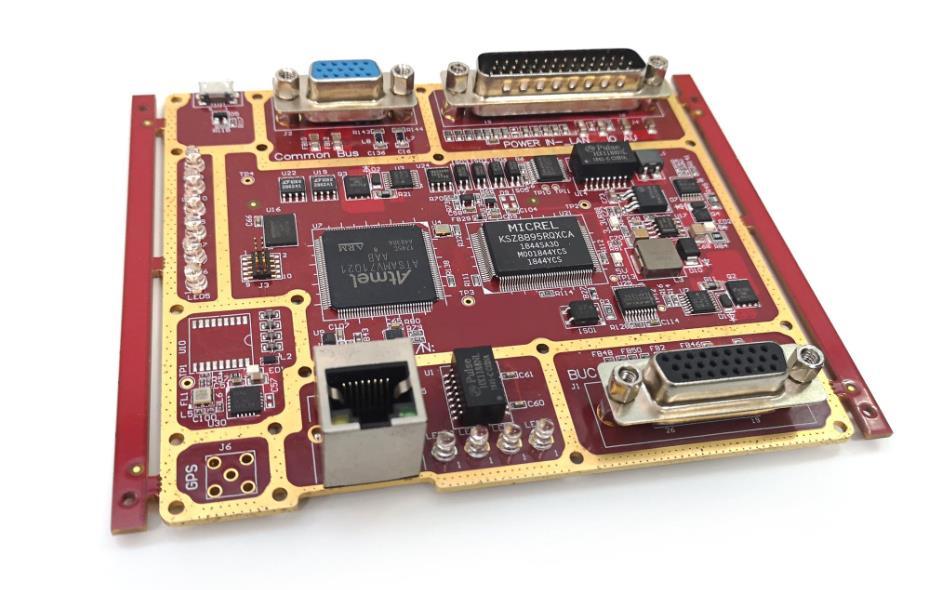

Display of our PCB assembly products

Our PCB assembly capacity

- SMT processing capacity

- Components and PCB specifications

| SMT capacity | 4 million solder joints per day |

| SMT production line | 5 pieces |

| Discharge rate | Resistance and volume ratio 0.3% |

| IC class no throwing material | |

| Board type | POP/ plain plate /FPC/ rigid flex bonded plate/metal substrate |

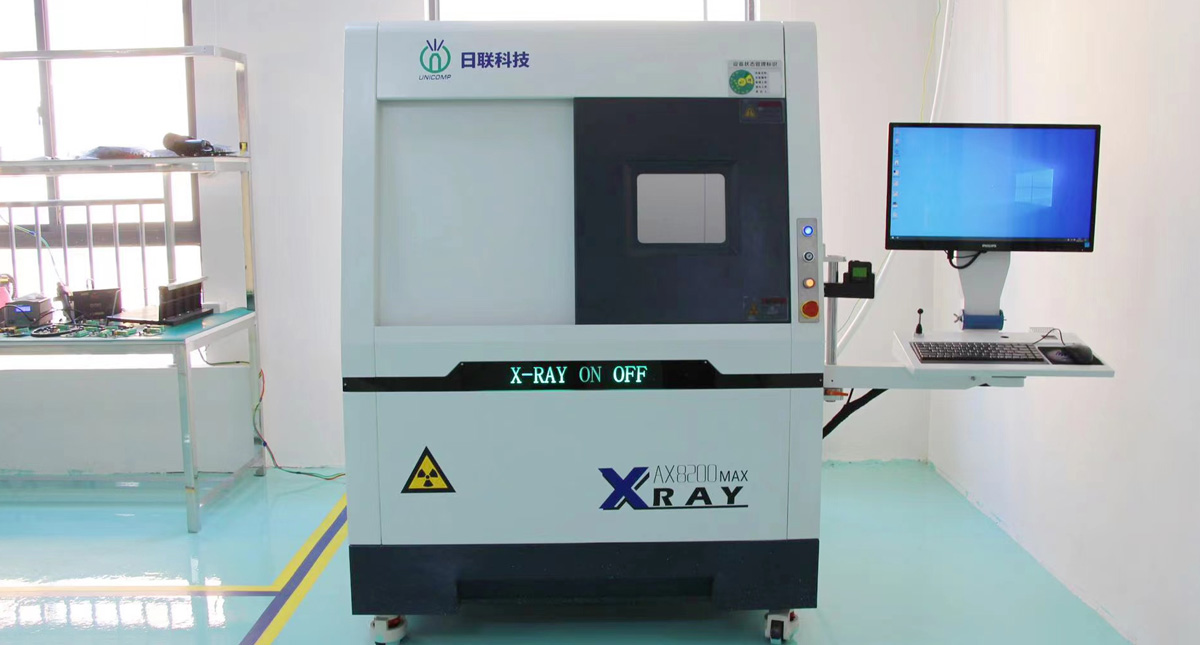

PCB manufacturing quality inspection capability equipment

Quality certification

Production testing equipment

Would you like us to provide you with PCB assembly services?

Request for quotationOur PCB assembly advantage

-

On-time delivery

Our own plant of 4000 square meters, and equipped with 7 automatic SMT lines and 2 DIP assembly lines. -

Quality assurance

We are equipped with online SPI, AOI, X-Ray testing equipment, product delivery qualified rate can reach 99.5%, in line with ISO, IATF, UL standards. -

Strong supply chain and engineering team

With more than 10 years of industry experience in supply chain and engineering team, we can not only provide customers with the fastest quotation service, but also provide high quality products and services.

PCB assembly FAQ

-

1What will happen to the remaining components after the SMT product is completed?

A:If you think these parts will be used again, we can keep your remaining parts in our inventory for use in the next order; Or we can ship spare parts with your completed order so that you can use them for troubleshooting and servicing.

-

2What documents are needed for SMT processing?

A: A bill of materials for the product should be providedBOM, PCB file, steel mesh file, bit number silk screen, component coordinate file.

-

3How to ensure the quality of products?

A:Our high quality standards are achieved in the following ways. All production processes are strictly in accordance with ISO IATF UL standard control, IQC incoming material detection: eliminate poor process caused by poor materials, and delay in delivery; SPI solder paste detection: detect the outflow from the front-end process to the next process in advance (inspection standard: 3D detection + data statistical analysis); Online AOI detection: check whether the products produced have errors, leakage, bad materials flow out of the next process; SMT first part testing: ensure that the components attached to the production model are fully in accordance with the customer's assembly drawing and bill of materials, to prevent defects from flowing into the next process (check each solder spot of the first part of the board by referring to BOM and Gerber data); Appearance inspection: Random inspection of all production processes to check whether they are in accordance with the operating instructions (effectiveness standard: process instructions of each product and instructions of each post); X-Ray welding detection: detect the welding spots of invisible components to avoid virtual welding short circuit flowing out of the next process;

BGA device repair: X-Ray detection of poor welding BGA disassembly and welding under temperature controlled conditions, reduce the impact on the device and ensure the quality of repair welding; QA inspection: standardize finished product inspection to prevent unqualified products from being shipped; Anti-static storage and shipment: anti-static packaging and safety protection storage.

-

4What are the customer's requirements for supplying materials?

A:Please do not buy or provide oxidized devices, it is not good for welding weldability, incoming materials please prepare adequate amount of material loss, material loss quantity, please contact with the salesman to confirm; Please attach the requisition sheet for incoming materials. If there are many kinds of products, please pack them separately. In case of a batch of bulk material, the price is calculated separately.

-

5Can SMT mount really achieve 23-hour delivery?

A:在We can deliver within 23 hours if the material is less than 50 pieces and complete the set, and SF package is delivered by mail.

-

6How to deal with the problem of processing products? Who should bear such responsibility?

A:If you find the wrong board after receiving the goods, or there is a production quality problem, please contact the business staff immediately, our company will not take or refund; Our company will not be responsible for the problems caused by the design. If there is a problem, we will try our best to remind the user.

-

7Is the component procurement channel of Baidian technology formal?

A:We have close20 people procurement supply chain team, according to your needs, with the most affordable price, for you to purchase all kinds of components, 100% original authentic, traceable source, minimize your labor costs.

-

8Can Baidian technology do mass SMT mounting?

A:Baidian Technology can certainly do mass SMT installation, you can first place a SMT proofing order, wait for you to receive our SMT proofing order, test no problem, then inform us to produce mass SMT installation. You can also send the PCB file to us for the basic inspection and confirmation of the project. Once confirmed, you can repeat this order and carry out batch production.

快发智造

快发智造